|

|

Superior Raw Material by Perfect Heat Treatment Precision

Process of all parts by CNC Machine Strong

Superior Raw Material by Perfect Heat Treatment Precision

Process of all parts by CNC Machine Strong |

... Power

and High Efficiency Faithful Service after sales

|

|

|

|

Unit |

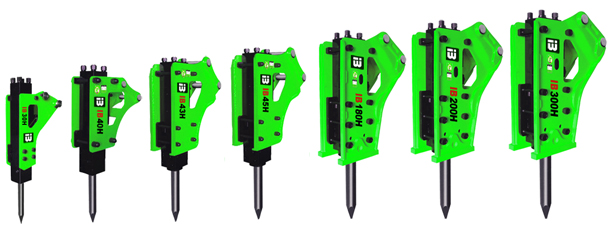

IB20H |

IB30H |

IB40H |

IB43H |

IB45H |

IB50H |

| Suitable

Excavator |

ton |

0.8~3 |

1.2~4 |

2.8~5 |

4~9 |

6~11 |

9~16 |

| Gross

Weight |

kg |

100 |

130 |

270 |

440 |

510 |

800 |

| Required

Oil Flow |

l/min |

20~40 |

25~50 |

30~70 |

40~80 |

50~100 |

80~110 |

| Operating

Pressure |

bar |

80~110 |

90~120 |

95~130 |

100~130 |

130~150 |

150~170 |

| Setting

Pressure |

bar |

150 |

150 |

170 |

170 |

195 |

210 |

| Tool

Shank Diameter |

mm(inch) |

45

(1.77) |

53

(2.1) |

68

(2.67) |

75

(2.95) |

85

(3.34) |

100

(3.94) |

| Impact

Rate |

bpm |

700~1,200 |

600~1,100 |

500~900 |

450~900 |

400~800 |

350~700 |

| Back

Head N2 Pressure |

bar

kg/§І |

16Ўѕ0.5 |

16Ўѕ0.5 |

16Ўѕ0.5 |

16Ўѕ0.5 |

16Ўѕ0.5 |

16Ўѕ0.5 |

| Hose

Diameter |

inch |

1/2 |

1/2 |

1/2 |

1/2 |

3/4 |

3/4 |

| Valve

Location |

|

Inner |

Inner |

Inner |

Inner |

Inner |

Inner |

|

|

|

|

Unit |

IB180H |

IB200H |

IB81H |

IB300H |

IB400H |

IB400HS |

| Suitable

Excavator |

ton |

15~18 |

18~26 |

18~26 |

27~35 |

32~50 |

32~50 |

| Gross

Weight |

kg |

1230 |

1740 |

1740 |

2420 |

2900 |

2780 |

| Required

Oil Flow |

l/min |

90~120 |

130~150 |

120~180 |

150~190 |

190~250 |

190~250 |

| Operating

Pressure |

bar |

150~170 |

160~180 |

160~180 |

160~180 |

160~180 |

160~180 |

| Setting

Pressure |

bar |

210 |

210 |

210 |

230 |

230 |

230 |

| Tool

Shank Diameter |

mm(inch) |

120

(4.7) |

135

(5.3) |

140

(5.5) |

150

(5.9) |

160

(6.3) |

155

(6.1) |

| Impact

Rate |

bpm |

400~900 |

400~800 |

350~500 |

350~700 |

300~600 |

300~600 |

| Back

Head N2 Pressure |

bar

kg/§І |

6Ўѕ0.5 |

6Ўѕ0.5 |

16Ўѕ0.5 |

6Ўѕ0.5 |

9Ўѕ0.5 |

9Ўѕ0.5 |

| Accumulator

N2 Pressure |

bar

kg/§І |

60Ўѕ0.5 |

60Ўѕ0.5 |

60Ўѕ0.5 |

60Ўѕ0.5 |

60Ўѕ0.5 |

60Ўѕ0.5 |

| Hose

Diameter |

inch |

3/4 |

1 |

1 |

1 |

1Ёщ |

1Ёщ |

| Valve

Location |

|

Outer |

Outer |

Outer |

Outer |

Outer |

Outer |

|

* Materials and specifications

are suject to change without prior notice.

|